Press contact

Would you like to write about SkyCell or schedule an interview? Please reach out to our Communications team for any media requests at pr@skycell.ch

May 2025

3 minute read

The conversation around AI is everywhere — especially in industries like pharma and medical device supply chains. But the challenge isn't just understanding AI; it's identifying where and how it can make a tangible, scalable difference.

At LogiPharma 2025, SkyCell CEO Richard Ettl joined industry leaders from Moderna, Zoetis, and ParkourSC to cut through the hype and explore practical AI applications that are already reshaping pharma logistics today — from monitoring equipment health to building intelligent, responsive supply chains.

The panelists agreed: AI has the potential to drive unprecedented productivity across the pharma value chain — but only if implemented thoughtfully.

Richard Ettl emphasized that while real-time monitoring systems exist, many organizations struggle to turn data into decisions. “This is where AI can come in,” he said. “You can have systems that can help you absorb the information, understand the content, make recommendations, and automate so that data becomes actionable. This is what I’m most excited about.” Rather than overwhelming teams with data, AI can filter signal from noise — helping operations teams focus on what truly matters.

Sebastian Lucas, VP at Zoetis, reinforced the human element: “We have to start with engagement, making sure people want to be trained.” Zoetis set a bold target of unlocking one million hours of efficiency gains per year by embedding AI into everyday tasks like drafting emails, summarizing PowerPoints, or automating SOPs. For Zoetis this is about more than automation — it’s a cultural shift toward digital fluency and augmentation.

Throughout the panel, the speakers shared some real-life examples of where they are using AI and where they are struggling. Sebastian Lucas from Zoetis shared how they're applying AI to detect early signs of equipment failure, enabling proactive maintenance and reducing costly downtime. Brian Thornley from Moderna described the challenge of producing seasonal vaccines on an accelerated timeline—where traditional planning systems fall short due to constantly shifting parameters. For Moderna, AI could offer a way to dynamically sense, predict, and adjust in real time, rather than relying on outdated assumptions.

Richard Ettl highlighted how SkyCell uses AI to help predict and prevent temperature excursions before they happen—turning passive data into proactive interventions. He also noted how AI enables better stock visibility, helping companies understand where inventory is, how fast it’s moving, and where it’s needed next.

AI’s potential isn’t a given — and the panel didn’t shy away from its obstacles.

Data quality remains a fundamental barrier. Brian Thornley, VP of Supply Chain Excellence at Moderna, highlighted the importance of robust data infrastructure: “You still have to have system records, you still have to have transactional systems, and therefore your master data has to be as good as possible, otherwise you just go towards chaos.”

The other key challenge? Change management. As AI automates more decision-making, organizations must bring people along for the ride. “It’s not a crystal ball,” moderator Mark Talens noted. “AI still needs feedback. You need people to engage with the system, to trust it, and to course-correct.”

A shared recommendation from every panellist was to start small, show results, and scale from there. They discussed the importance of clearly defining what you want to achieve with AI and knowing how you can get there in small jumps. What are you solving for?

When asked to predict the future, Richard Ettl offered three bold forecasts:

At SkyCell, we’re not just talking about the future — we’re building it.

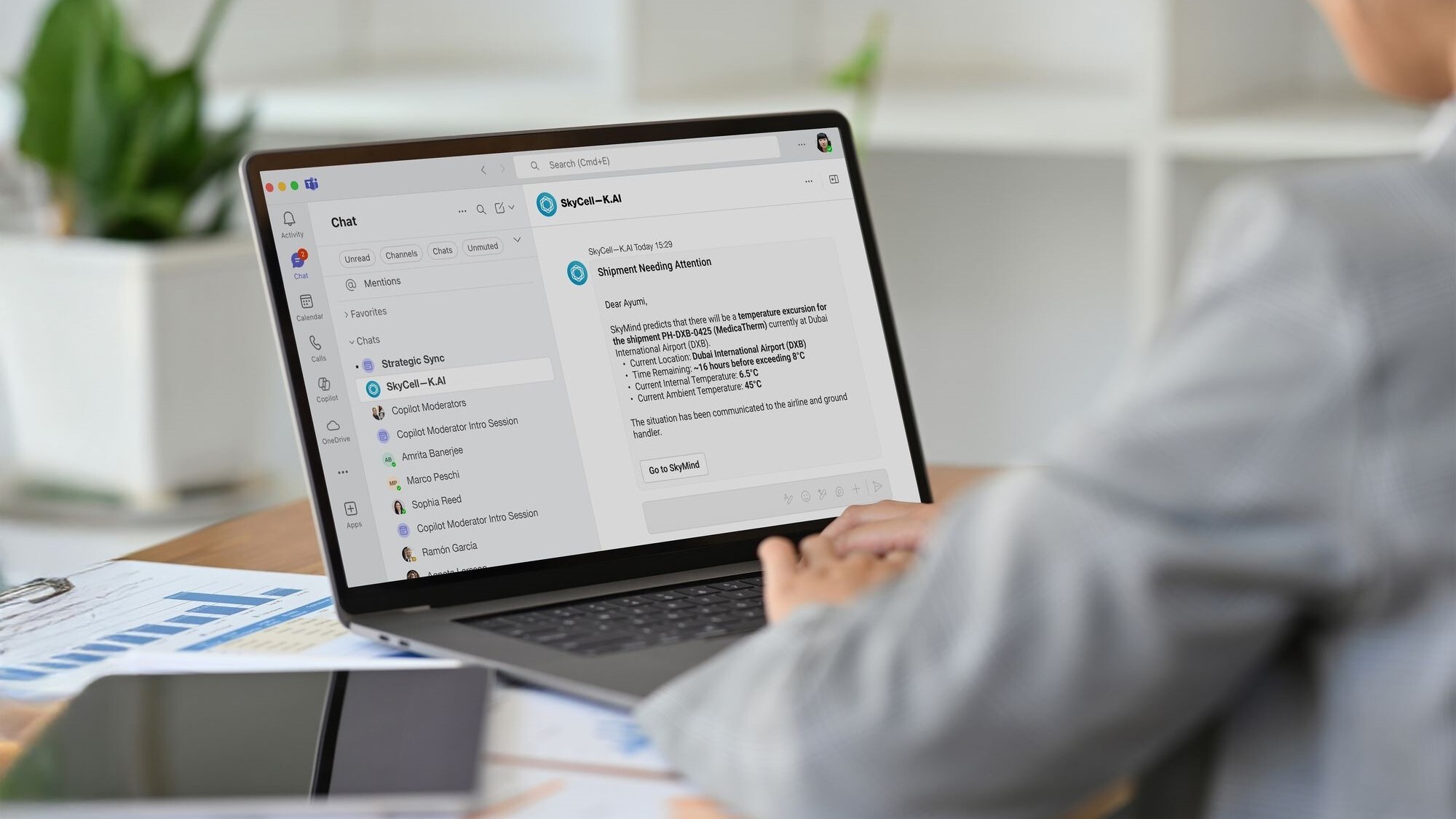

Our new collaboration with Microsoft enables our intelligent assistant, K.AI, to seamlessly connect stakeholders via Microsoft Teams whenever issues arise in the supply chain. K.AI can provide real-time updates and alerts alongside recommendations based on internal SOPs and external data.

This integration helps facilitate timely shipment interventions, ensuring that temperature-controlled pharmaceuticals are delivered with precision. With AI’s ability to process data in real time, pharma companies can address issues before they escalate, ultimately improving the reliability and efficiency of their supply chain operations.

This advanced AI capability will be a core component of our latest pharmaceutical monitoring service, designed to provide even greater visibility and control across the supply chain. To learn more about how this solution can support your operations, visit our website.

Would you like to write about SkyCell or schedule an interview? Please reach out to our Communications team for any media requests at pr@skycell.ch