In pharmaceutical logistics, every shipment matters. The medicines inside are highly sensitive, the regulations around them are exacting, and the cost of failure is measured in more than money.

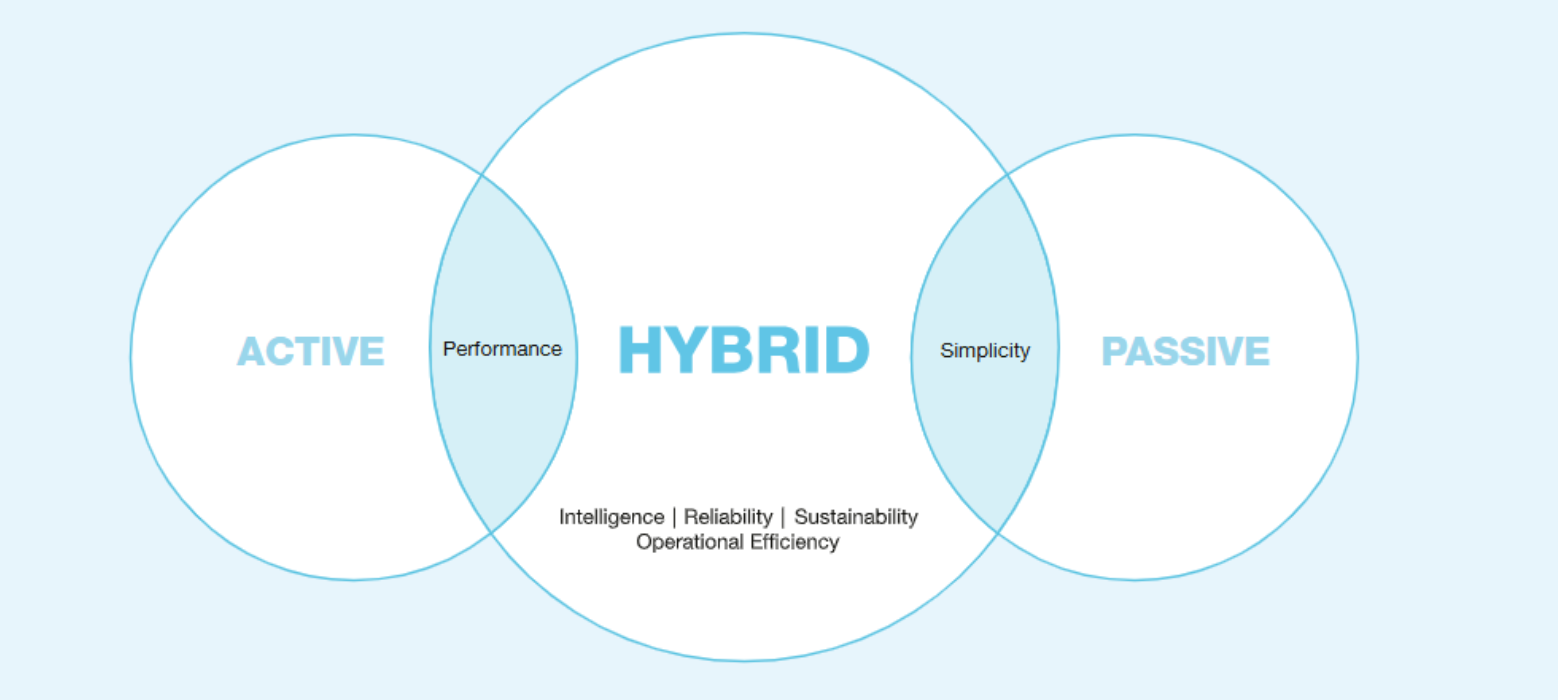

Yet, for years, pharma companies have had to choose between imperfect options.

Active containers can offer reliable temperature control, but they depend on power, require specialized handling, and add CO2 with every charged or air-returned unit. Passive packaging, meanwhile, is often lighter and doesn’t require power plugs, but struggles in extreme temperatures with poor visibility.

The result? A constant balancing act between performance, efficiency, sustainability, and intelligence, where improving one often means compromising another.

The Supply Chain Trade-Offs Pharma Shouldn’t Have to Make

Performance: Temperature excursions still cost the industry billions each year. According to IQVIA, over $35 billion in pharmaceutical products are lost annually due to breaks in temperature control. Both active and passive are too limited in the performance they offer when faced with global pharma flows.

Efficiency: Active units demand charging, roller beds, and manual checks that slow operations. Passive solutions require extra packaging or temperature-controlled vehicles, adding weight and cost. Both place heavy demands on already overloaded warehouses.

Sustainability: With pressure to cut emissions, active containers’ high energy use and air returns, and passive packaging’s single-use waste are becoming untenable.

Intelligence: Once shipments leave the manufacturing site, visibility often drops. Many systems still rely on manual checks or USB data loggers that only provide data post-shipment, making risk management reactive rather than predictive.

It’s a problem everyone in cold chain logistics knows, and one SkyCell set out to solve.

Hybrid: A Solution for Tomorrow’s Supply Chain Challenges

Hybrid containers bring together the best of existing systems:

- Performance of active containers, maintaining proven protection for over 270 hours at 20 °C, with an excursion rate of less than 0.05%.

- Efficiency of passive solutions; no plugs, charging, or roller beds required, with a lightweight design that maximizes payload and minimizes weight.

- Sustainability through a circular, reusable model cutting lifecycle CO₂ by up to 50% and with Net ZERO Reverse ocean returns.

- Intelligence with built-in IoT sensors providing live data and predictive insights for full visibility and control from origin to destination.

Hybrid = Performance + Efficiency + Sustainability + Intelligence.

It’s a simple equation that removes the industry’s biggest trade-offs. Our latest white paper, Understanding Hybrid Containers, unpacks this equation in detail, showing how hybrid technology reshapes pharmaceutical logistics from design to delivery.

> Download the White Paper