Press contact

Would you like to write about SkyCell or schedule an interview? Please reach out to our Communications team for any media requests at pr@skycell.ch

Nov 2025

3 minute read

Pharmaceutical products are only as stable as the environments they travel in. Even a single inspection that requires containers to be opened can result in an entire batch being thrown away. To tackle this, the cold chain must remain unbroken, from the moment a container is sealed at origin until it is opened at its final destination.

For most containers, their weakest link is airports. Around the world, aviation regulators demand that all air cargo undergo approved screening before entering the hold of an aircraft. The problem is that many active and passive containers are either too large to fit into standard airport X-ray machines, contain dense battery systems, or have insulation that obscures scans, triggering alarms and forcing security teams to open the container. Each time this happens, products are exposed to ambient conditions, introducing risks that no pharmaceutical company can afford.

The operational impact is just as serious. Unpacking and reloading at airports requires extra manpower, increases handling time, and introduces human error. In some locations, restrictions on screening active containers have even forced cargo to be rerouted to other airports, adding delays, cost, and complexity to already delicate shipments. Many regions also impose restrictions on screening methods (e.g., no sniffing dogs or limited handling zones), making X-ray scanning the only solution that can keep the cold chain intact.

SkyCell’s 1500X container was engineered with airport screening in mind. Its design fits neatly into standard X-ray machines, ensuring smooth scanning without unloading. Unlike active containers, the 1500X does not trigger DARC alarms, and security personnel can see a clear, unobstructed scan of the cargo inside. This avoids the need for physical inspections, keeping the container sealed and the internal temperature stable.

By making X-ray scanning possible, the 1500X enables true door-to-door transport at scale. Once the shipment is loaded at its origin, it can remain sealed all the way through to the final delivery. The result is fewer handovers, lower risk of temperature excursions, and faster customs clearance, supporting the safe and reliable delivery of pharma products worldwide.

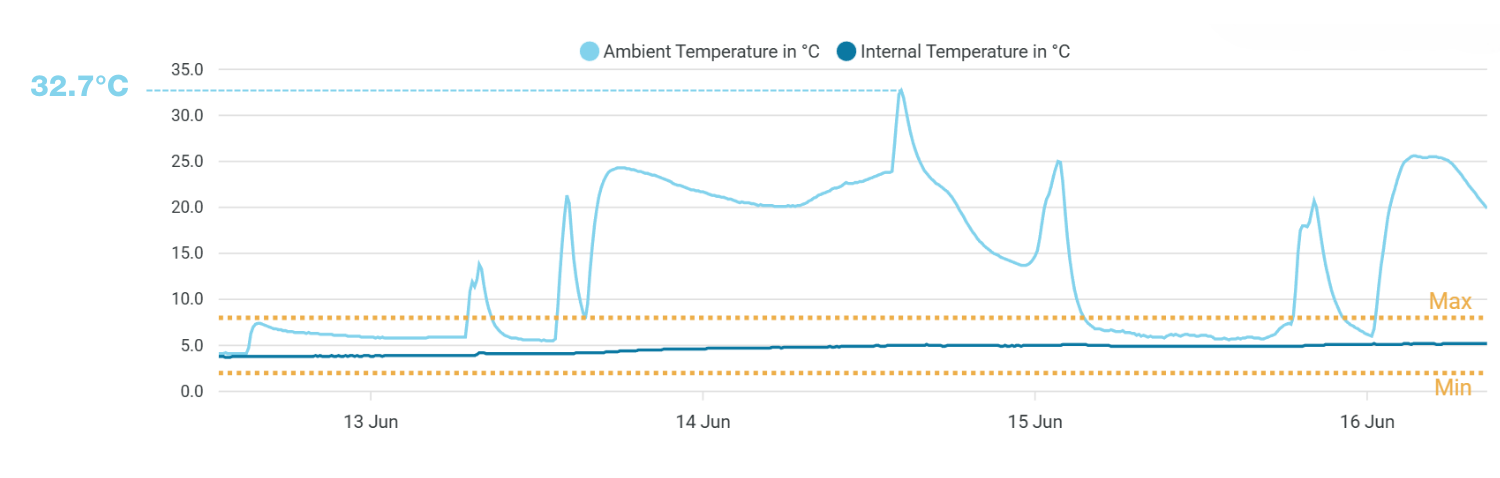

As part of an ongoing partnership, Biocon Biologics Limited recently entrusted SkyCell with a shipment of pharmaceutical products from London Heathrow (LHR), United Kingdom, to Casablanca (CMN), Morocco. Over the three-day lease, the 1500X-COL containers endured challenging external conditions, with temperatures ranging from a cool 5.5°C to a sweltering 32.7°C. During customs, the container remained sealed, passing smoothly through the X-ray machine and maintaining a stable internal environment throughout its journey.

Ananda S Chatterjee, Director – SCM (Lead Continual Improvement) at Biocon Biologics Limited, described his experience of uninterrupted cold chain with SkyCell and noted that in each shipment there has been "no spike in temperature even during the customs screening and processing" highlighting that the 1500X is a “One-of-a-Kind Solution in the Cold Chain Industry.”

Biocon Biologics Limited's shipment demonstrated how the 1500X's X-ray compatibility and careful design support an unbroken cold chain. The containers protect temperature-sensitive pharmaceutical products from origin to destination, delivering the same reliability at scale, no matter the shipment size, while minimizing handling and risk at every point.

The 1500X is a “one-of-a-kind solution in the cold chain industry.”

The importance of X-ray compatibility is only set to grow. Aviation authorities worldwide are tightening security rules, increasing both the scope and depth of cargo screening. For example, Japan will introduce stricter Explosive Trace Detection protocols in 2026, meaning the ability to successfully be screened using an X-ray machine will become a decisive advantage.

Beyond Japan, updates to IATA’s Temperature Control Regulations (TCR) in 2026 and the ongoing evolution of TSA and ICAO cargo security roadmaps point toward a future where screening will be more stringent than ever. Both active and passive packaging complicate the screening process and are usually not compatible with X-ray machines. Pharma companies and logistics providers need a scalable solution that not only protects the cold chain today but is already compliant with tomorrow’s standards.

The 1500X delivers exactly that. By ensuring seamless passage through airport X-ray checks, it safeguards the cold chain, minimizes delays, and enables true door-to-door delivery at scale and across borders while future-proofing the supply chain in an increasingly complex regulatory environment.

Can pharmaceutical containers go through airport X-ray machines?

Many pharma containers cannot pass through standard airport X-ray units because of their size or internal components. This often forces manual inspection, resulting in delays and added risk. The 1500X is designed carefully to ensure it fits in standard X-ray machines without any components that would trigger DARC alarms.

Are active temperature-controlled containers compatible with X-ray scanning?

Many active units are not compatible because dense battery systems interfere with imaging. This often results in them being opened for inspection, exposing the products inside to ambient temperatures. Alternatives like the SkyCell 1500X hybrid container are X-ray compatible, reducing risk in airports where the majority of excursions occur.

Will future aviation regulations make X-ray compatibility essential?

Countries are tightening cargo security standards. Screening requirements will increase. A container that already meets these expectations prepares shippers for upcoming regulatory changes.

Would you like to write about SkyCell or schedule an interview? Please reach out to our Communications team for any media requests at pr@skycell.ch